USFAB sources a wide variety of high- quality metal finishing services from a large, experienced network of domestic vendors. Metal Finishing enhances the physical land mechanical properties of fabricated metal components.

Drawing on over four decades of experience, our knowledgeable staff can achieve almost any type of finish for virtually any application or environment.

To further support our customers’ needs, we offer a broad range of capabilities including precision laser cutting, CNC machining, and welding. These in-house services enable us to provide single-source solutions for our customers’ diverse metal fabrication needs.

For unique projects with highly specialized requirements or specifications, USFAB also partners with local certified suppliers and industry professionals to handle customized jobs.

Benefits of Metal Finishing

Metal finishing alters the surface of a metal workpiece to achieve specific characteristics. Following the initial metal component’s fabrication, finishing operations typically enhance one or more of the following properties:

Surface quality

Adhesiveness

Electrical conductivity

Corrosion resistance

Wear or abrasion resistance

Chemical resistance

Frictional resistance

Solderability

Weldability

Aesthetics

Dimensional accuracy

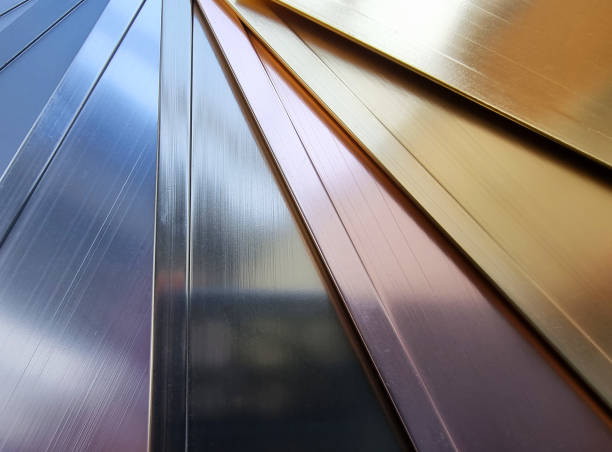

Types of Metal Finishes

USFAB’s experienced technical staff and state-of-the-art finishing equipment achieve a variety of finishes on almost any metal or alloy surface. Some of our finishing services include:

Annealing – Also known as heat treating, this process reduces metal hardness, enhances ductility, and improves machinability.

Anodizing – An electrochemical process that passivates a metal surface by creating a corrosion-resistant oxide finish, this method can also be integrated with various colors for decorative purposes.

Coating – Offering several traditional coating services including powder, phosphate, epoxy, and Teflon coating, USFAB can also apply customized surface coatings in accordance with customer requirements.

Deburring – Using grinding, tumbling, and vibratory deburring techniques to remove rough or jagged edges produced during manufacturing, deburring is typically employed to enhance metal appearance and improve dimensional tolerances.

Electropolishing – This electrochemical process removes unwanted material from a metal workpiece. Ideal for making a metal surface featureless, electropolishing can be used as an alternative to traditional mechanical methods such as grinding, milling, blasting, and buffing.

Laser marking/engraving – Utilizing cutting-edge laser technology, laser marking produces precise and high-quality engraving (lettering or patterns) on a variety of metal or alloy surfaces.

Plating

Metal plating applies a thin layer of metallic coating on a metal surface to improve specific properties such as its corrosion resistance, appearance, strength, and conductivity. USFAB’s range of metal plating capabilities includes:

- Black Oxide

- Cadmium

- Chromate

- Copper

- Electroless Nickel

- Gold

- Nickel chrome

- Rhodium

- Silver

- Tin

- Zinc

In addition to our finishing services, USFAB also performs various tests to assess the corrosion resistance of metal components, including:

Coating thickness

Coating weight

Hardness

Humidity

Salt spray

Ready to get started with USFAB on your next metal fabrication project? Contact a member of our team today.